Agresti Energy is a global company headquartered in Indianapolis, Indiana, USA. We are “turbo charging” the agricultural, municipal sludge and landscape waste markets. Our process utilizes the cellulosic materials that are not destroyed in a traditional anaerobic digester system, doubling even tripling, the energy, cash flow and profits by taking what is currently a waste product and converting to energy. We are using existing Federal and State incentives for cellulosic renewable energy production. Including our own Agresti Energy USEPA approved pathway. Our technology is unique, disruptive and is transforming how the world views cellulosic waste streams. Agresti IS changing the landscape for cellulosic material to energy production. Our process converts waste into a variety of biogas energy products at a speed and efficiency unmatched by any other technology. Our process is clean and creates energy production that improves the environment.

AGRESTI PRESSURE HYDROLYSIS PROCESS (PHP)

Agresti Energy has developed a “blueprint” for doubling AG digester capacity producing cellulosic RNG. Our PHP process is adaptable to producing bio-LNG, bio-CNG, bio-ethanol, bio-butanol and bio-plastic. An Agresti plant can process cellulosic waste streams such as manure, digestate, crop residue, sewer sludge, agricultural waste, food and beverage waste, paper, garden and wood waste. The cellulose from these waste streams are converted to C5 and C6 sugars.

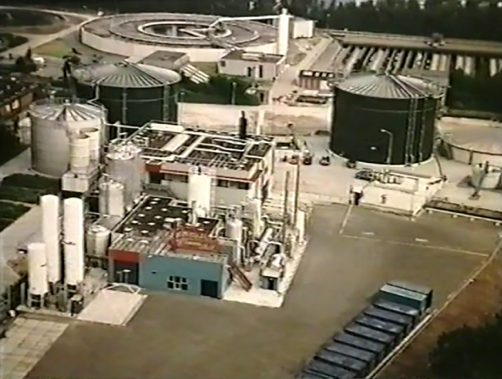

While our technology appears to be “new”, it really isn’t. A facility in Apeldoorn, Netherlands operated from 1992 to 2008. It was a commercial cellulosic sewer sludge processing plant using wet oxidation. An Agresti founding partner, Dr. Roelof Niezen helped design, build, and maintain this Vertech plant until it was dismantled in 2008. The sludge contract had expired, and Apeldoorn chose to develop the site to accommodate the city’s growth. The aftermarket programs did not then exist in Europe to take advantage of the C-5 and C-6 sugars producing renewable energy.

However, in the United States, the Renewable Fuels Standard (RFS) implemented by the Energy Independence and Security Act of 2007 (EISA) provides for just such an aftermarket market. Under this Act, the goal is to achieve 36 billion gallons of annual biofuel use by 2022. Sixteen billion gallons or 44% of this goal is reserved for cellulosic biofuel as produced by Agresti’s PHP. Current cellulosic production is less than 400 million gallons or roughly 2.5% of the goal. This means production must increase 40X to meet mandated demand. This represents a significant scalability opportunity for the Agresti PHP.

Apeldoorn Netherlands: Plant Layout

The headworks of the Wet Oxidation reactor vessel named R 201.

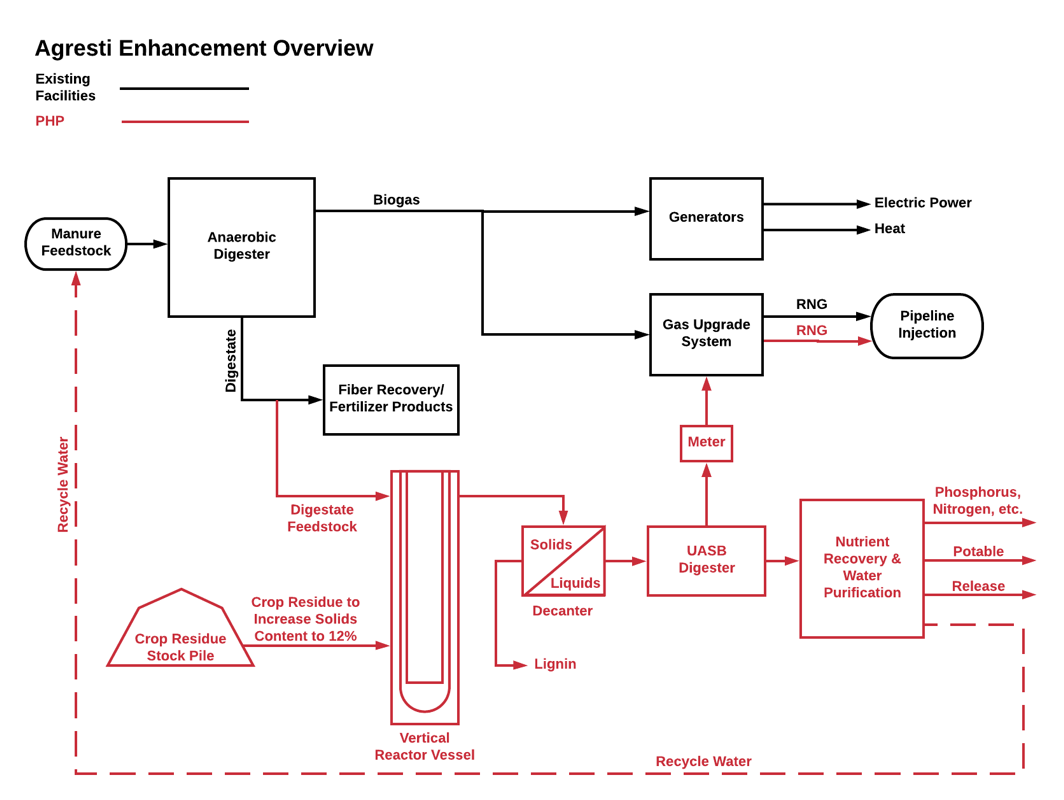

A standard Agresti plant with the PHP technology consists of 4 constituent parts:

Part I Anaerobic Digester

Part II Digestate processor – Agresti Energy PHP technology, with our vertical reactor vessel being the primary component

Part III Gas upgrade system, transmission pipeline injection point

Part IV Final water cleaning & nutrient recovery components

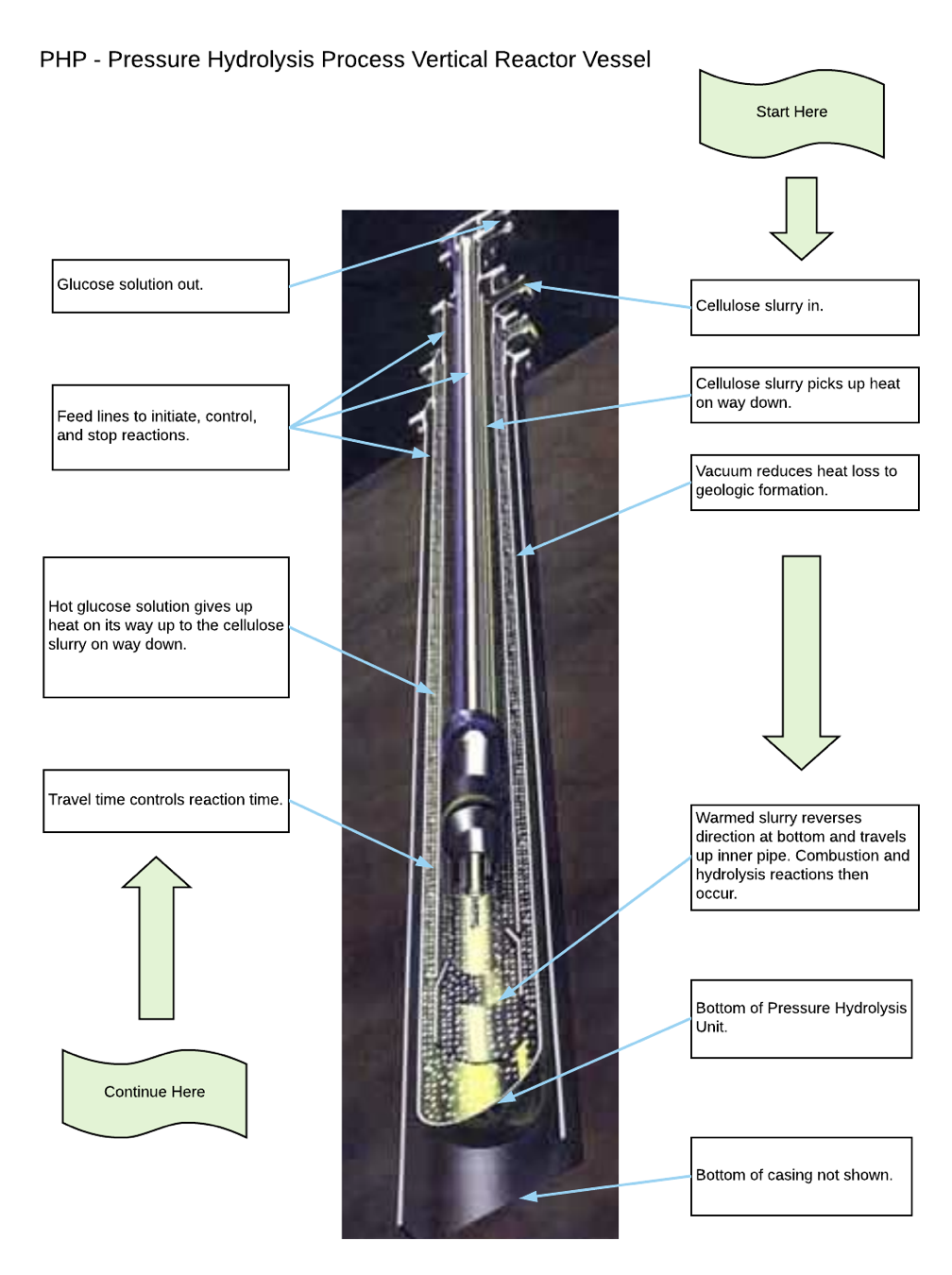

The PHP consists of a vertical reactor vessel at a depth of 2,000 feet in the ground. It is simple, efficient, and clean. It can process a broad range of cellulosic waste streams.

The PHP technology converts cellulose to sugars by using a well-known chemical process called weak acid hydrolysis. Phosphates, nitrogen and other inorganic materials can be further separated by conventional water purification technologies. The sugars are converted to biogas using an anaerobic digester (UASB). The CO2 is partially reused to produce carbonic acid for the PHP. The remaining CO2, if not released, can be liquefied and sold as a product. Combined biogas production is DOUBLED compared to conventional digesters alone.

DIAGRAM: PHP TECHNOLOGY CONVERTING CELLULOSE TO SUGARS

DIAGRAM: PHP PROCESS CAN BE ADDED TO EXISTING DIGESTER FACILITIES

SUMMARY

Agresti offers for digestate treatment a clean, proven technology. Our process does the following:

Doubles the energy produced with associated revenues enhanced by D3 RINS and LCFS credits.

Removes all organic material allowing for established technology to clean the water (for recycling, release, and or potable uses), and nutrient recovery (nitrogen, phosphates, salts, etc.)

Eliminates the need to haul, inject or spread digestate byproducts and associated water.